|

|

|

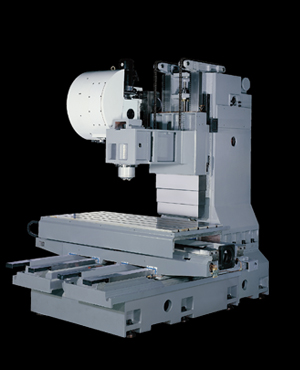

| Extra Wide 1100mm Four Box Way. |

Built-in Type 6,000rpm Gear

Head (BT50).

|

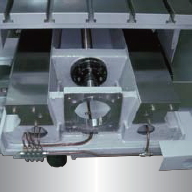

X+Y+Z One Piece Casting With

Direct Coupling Drive.

|

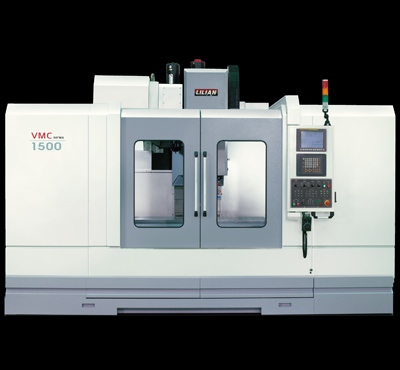

| VMC-1100 | VMC-1400 | VMC-1500(G) | VMC-2000(G) |

||

| Working Table |

Table Size | 1150 x 610mm | 1550 x 700 mm | 1550 x 700 mm | 2100 x 800 mm |

| T-Slot (width x dis.x no.) | 18 x 130 mm x 5 | 18 x 130 mm x 5 | 18 x 130 mm x 5 | 22 x 125 mm x 6 |

|

| Travel (X x Y x Z) | 1100 x 610 x 610 mm | 1400 x 720 x 610 mm | 1500 x 720 x 680 mm | 2000 x 850 x 750 mm |

|

| X/Y/Z-Axis Motor (Z axis with Brake) |

2.5 / 2.5 / 2.5B kw | 4 / 4 / 4B kw | 4 / 4 / 4B kw | 4 / 7/ 7B Kw |

|

| Rapid Feed Rate (X/Y/Z) |

15 x 15 x 15 M/min (18M/min Opt.) | 15 x 15 x 15 M/min (18M/min Opt.) | 15 x 15 x 15 M/min (18M/min Opt.) | 12 x 12 x 10M/min |

|

| Feed Rate (X/Y/Z) | 1-10000 mm/min | 1-10000 mm/min | 1-10000 mm/min | 1-10000 mm/min |

|

| Max. Table Load | 1000 kgs | 1200 kgs | 1500 kgs | 2200 kgs |

|

| Spindle | Taper | BT40 | BT40 | BT50 (Gear Head) | BT50 (Gear Head) |

| Main Motor | 11 / 15Kw | 11 / 15Kw | 15 / 18.5 Kw | 15/18.5 Kw |

|

| Spindle Speed (RPM) | 8000 / 10000 | 8000 / 10000 | 6000 | 6000 |

|

| Spindle Nose Vertical to Table Surface | 100-710 mm | 150-760 mm | 164-844 mm | 150-900mm |

|

| Spindle Center to Column | 695 mm | 745 mm | 745 mm | 870 mm |

|

| Tool Magazine | Tool Storage Capacity (PCs) / ATC Type |

24 /30(Opt.) ARM Opt. 40 CHAIN |

24/30(Opt.) ARM Opt. 40 CHAIN |

24 ARM Opt. 40 CHAIN | 24 ARM Opt. 40 CHAIN |

| Max. Tool Diameter / Weight | 80 mm / 7 kgs | 80 mm / 7 kgs | 125 mm / 15 kgs | 125 mm / 15 kgs |

|

| Miscellaneous | Air Requirement | 6 kg/cm2 | 6 kg/cm2 | 7 kg/cm2 | 7 kg/cm2 |

| Power Requirements (KVA) | 25 | 25 | 30 | 30 |

|

| Coolant Tank Capacity (L) | 300 | 300 | 300 | 300 |

|

| Machine Weight | 7,500 Kgs | 11,500 Kgs | 12,000 Kgs | 14,500 Kgs |

|

| Machine Layout (W x D x H) | 2960 x 3130 x 2920 mm | 3840 x 3320 x 3040 mm | 3940 x 3320 x 3100 mm | 4900 x 3780 x 3500 mm |

|

| STANDARD ACCESSORIES | |

| ‧Coolant System ‧Auto Lubrication ‧Spindle Air Blast ‧Compact Fluorescent Work Light ‧Alarm System ‧Work Air Blast ‧Rigid Tapping ‧Heat Exchanger |

‧Enclosed Splash Guard ‧Auto Tool Changer ‧3 Axes Telescopic Steel Guard ‧RS232/ RJ45/ USB Interface ‧Auto Power Off (M30) ‧M.P.G ‧Level Pads & Bolts |

| OPTIONAL ACCESSORIES | |

| ‧Chain Type Chip Conveyor &

Chip Cart ‧Oil Coolant ‧Coolant Through Spindle (20~70 Bar) ‧CNC Rotary Table ‧Upgrade Motor ‧TS 27R Tool Setting ‧OMP40 / OMP60 Work Piece Setting |

‧Isolate type Transformer ‧Voltage Stabilizer ‧Angle Encoder (A,B,C axis) ‧Air Cooler for Control Box ‧Oil Skimmer ‧Air Gun & Water Gun |

| ‧Germany brand Heidenhain X+Y+Z axis Linear Encoders | |